Chorzów 17-05-2024

Factory in Chorzów Alstom Konstal.

The Konstal Factory, and currently Alstom Konstal is a company that was founded in the Prussian times in Upper Silesia in Chorzów in 1864. Currently, the factory in Chorzów is involved in the production of rail vehicles, mainly subway trains, trams and trains.

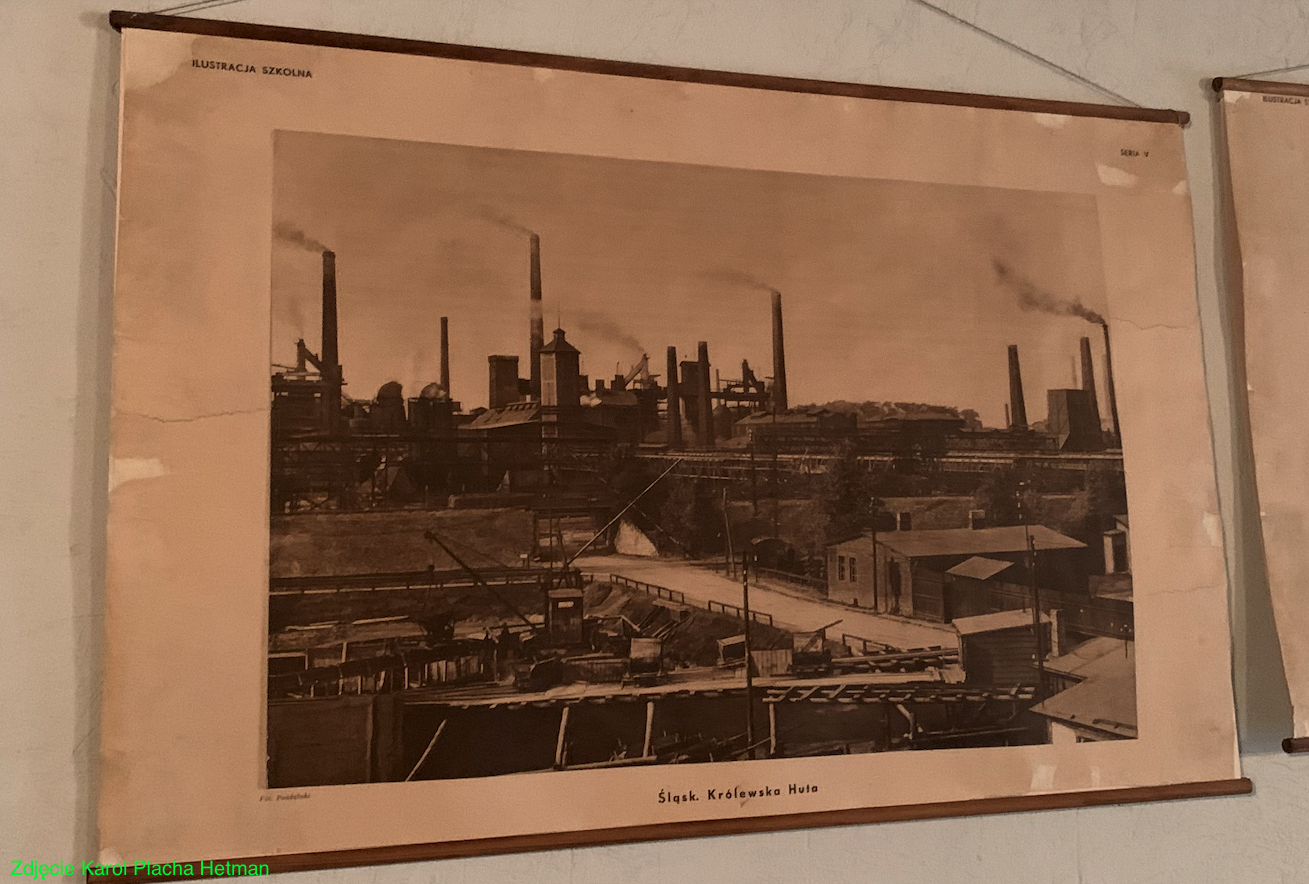

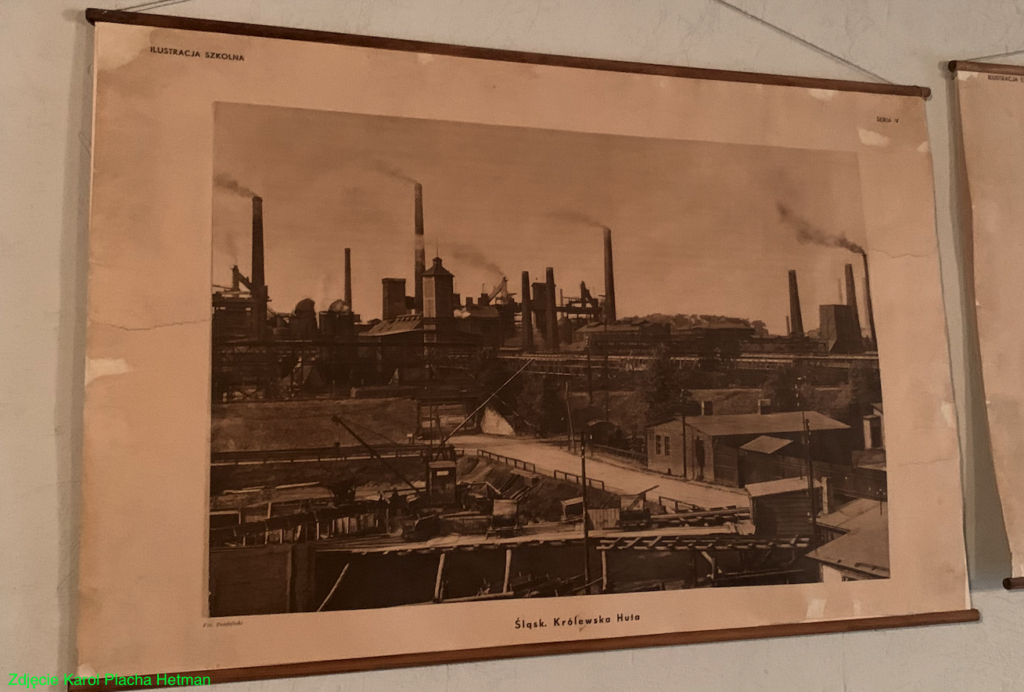

The factory was founded in 1864 as part of the Royal Huta. Huta was founded at the end of the 18th century, as Pruska Königshütte (Huta Królewska). In Poland, it received the name Huta Piłsudski, and then Huta Kościuszko. The plant is one of the oldest Polish iron smelters. In 1917, the factory was excluded from the structures of the smelter and became a separate production entity.

After the German army’s attack on the Polish -Lithuanian Commonwealth, the factory was included in the Reichswerke Hermann Göring concern and produced the German war.

After the Second World War, the factory was nationalized, under the decree, about the nationalization of industry in Poland of January 3, 1946, for compensation. The state took over all enterprises in seventeen industries. The factory received the name – the Konstal Steel Steel Structure Factory. The factory has become the main supplier of trams for the whole country and rolling stock and various steel structures for Poland and other RWPG countries.

Since 1997, the factory in Chorzów is part of the International Consortium of Alstom.

The beginnings of the factory in Chorzów (1864–1918).

The factory as a branch of Royal Huta received the name processing workshop (Germanic Verarbeitungswerkstätte). The first products were nails, bolts, rail pads, switchboards and other parts of rolling stock. In 1870, the steelworks and processing workshops were privatized and bought by Hugo Henckel von Donnersmarck, who was also the owner of the Laura Huta in Siemianowice Śląskie. It was a time when the Germans defeated the French army and France was forced to pay large contributions.

On June 2, 1871, a new joint -stock company was established with the headquarters in Berlin. The company received the name; United Huta Królewska and Laura Spółka Akcyjna for mining and metallurgy, in Germanic Vereinigte Königs- und Laurahütte Actien Gesellschaft für Bergbau und Hüttenbetrieb. The processing workshops have been expanded. The Faculty of Production Department of Kuvena and Rolling Rolling Stores was opened.

In 1894, the production of bridges and steel structures was launched. In 1895, in new halls, with an area of 10,000 m2, the production wagon production department was launched. The range of produced wagons was constantly increasing in the factory; Postal wagons, tanks (for oil, kerosene, alcohol), alive wagons, pot wagons (for the transport of chemicals at chemical factories), specialized wagons for transporting hot salads in steelworks. In 1908, a spring production department was launched. In 1917, the factory was excluded from the structures of the steelworks and the Royal Huta workshop management board was called (in Germanic Werkstättenungung Königshütte). At that time, the Great World War was underway, which the Germans began.

Interwar period (1918–1939).

In 1922, as a result of the Silesian uprisings, part of the Upper Silesia was joined to the Polish Republic, in which some mines, steel mills and factories were located. The company name was changed to the Upper Silesian United Huta Królewska and Laura Akcyjna Spółka in Katowice. The company remained a joint -stock company, still managed by the Germanians. This situation turned out to be a mistake. The Germans did not want to cooperate. They blocked the free flow of goods and began the customs war. The Germanic policy consisted of bringing to the bankruptcies of companies operating in Poland, even those under the management of Germanic people. In 1925, the Germanic people completely suspended the export of goods from Poland to Germani. For this reason, Poland has built a system of railway trails totaling Germanic areas, a sea port in Gdynia and a central industrial district.

In 1929, the New York was created Consolidated Silesian Steel Corporation, whose 30% of shares belonged to Bank Brown Brothers & Company, and the remaining 70% to German banks. The company included most Germanic enterprises in Upper Silesia, including Katowice Akcyjna for mining and metallurgy and the Upper Silesian United Huta Królewska and Laury Spółka Akcyjna in Katowice, whose 10% of shares belonged to the Polish Treasury. Officially, the Germans declared the development of companies, but in fact they sought their bankruptcy. Therefore, on March 29, 1934, the court in Katowice established court supervision over them. In 1936, the Polish side merged the companies to the newly created community of mining and metallurgy interests, a joint-stock company in Katowice, whose 80% of shares had the Polish mining and metallurgical union, and 10% after 10% was in the hands of the Polish Treasury and the United Silesian Steel Society. In 1938, it was the largest concern in Polish Upper Silesia. It consisted of processing plants of the Community of Mining and Hutnici Interests of the Akcyjna Spółka in Katowice.

At that time, the plant in Chorzów expanded the production range with trams for Upper Silesia and Warsaw and mine railway cars, as well as radio transmitters masts, parachuting towers, transhipment devices for the port in Gdynia and military pontoon bridges. In 1939, the first welded passenger wagons were made.

Time of the Germanic occupation (1939–1945).

And once again the Germans began the world war, together with their brothers Muscovites. On December 11, 1939, the Germanic army took the factory in Chorzów, and on March 27, 1940, the German administration entered the factory. The estate of the Mining and Metal interests Für Berg- und Hüttenbetriebe Hermann Göring. Poles were thrown out of managerial positions. Several hundred employees were taken deep into Germania for forced labor. Several dozen employees, mainly former participants of the Silesian uprisings, were sent to concentration camps.

The product range has changed in the factory. Production of guns and cannons began. A tinner was erected in the site of the railway turnout department. The wagon department began producing submarine hull segments, dry docks and lavet guns. Few Polish employees remained in the plant, mainly those signed by Deutsche Volksliste. Prisoners of war and prisoners worked mainly at the factory, under the watchful eye of Kapo. When the Soviet front was approaching, the Germans planned to level the factory with the ground, but they ran out of time. They only damaged the boiler room, power plant, air compressors, cranes and transport carts. The Germans took 120 machine tools.

On January 27, 1945, wild troops of Muscovites entered the city of Chorzów. There were clashes of Germanic troops with Soviet. The administrative building at the main gate was destroyed. Factory halls have been devastated. The Soviets unleaded machines pulled out the tanks outside and placed near the railway tracks, with the intention of their deportation to Moscow. However, there were no locomotives and wagons. Strong frost caused their further damage. Frost destroyed the water supply and central heating installation.

It wasn’t until February 1945, after the Soviets’ departure, Polish workers returned to the factory and began with the factory. Debris was removed. The broken windows are protected with sheet metal and wood. Piece was put into the halls and they were heated. Fixed water and central heating installations. Already on February 5, 1945, the first central heating boiler worked. About 90 Poles worked with these robots. Directorate, accounting, industrial and fire guard, human resources, provisions and supplies were reactivated. On February 9, 1945, pneumatic hammers were already working. The factory was named; Processing workshops in Chorzów.

The factory’s first success was the new steel bridge in Chorzów Batory. Successively launched; Forge, pressing house and department of springs. It began with the renovation of the wagons. A team was sent from the plant to Warsaw to recover the damaged spans of the Poniatowski Bridge through the Vistula. At that time, new spans were already built in Chorzów for this bridge. Wagons of carbon trucks were renovated and new production began. For Warsaw, trams were renovated and new ones were produced.

Mosto-Wagon and Konstal (1945–1997).

In the summer of 1945, the factory received the name; Chorzowska Wytwórnia Mostów and Wagons (in short Mosto-Wagon). In December 1945, 1,853 employees worked in the factory, and in March 1946, 2,812 people. In the first post -war years, the basic production of the factory were bridges and other steel structures, freight wagons and trams as well as rail and tram switches. On May 1, 1946, the plant was delivered by a hundredth new wagon; Coal. In the summer of 1946, the construction department of tram and rail trolleys was launched for the normal and narrow track. The number of machines and devices, also obtained from abroad, was systematically increasing in the factory.

At that time, there were plans to create a joint -stock company. However, by virtue of the decree, about the nationalization of industry in Poland of January 3, 1946, for compensation, all enterprises were taken over in seventeen industries and the factory in Chorzów became state. The document on this matter was issued on September 5, 1947.

In 1946, the new communist authorities decided that mass communication in cities would be based on tram transport. On October 17, 1946, a conference was organized in this matter in Katowice. Apparently, the effect of this conference was the decision to based the construction of Polish trams on the construction of the Germanic tram of the war, which was referred to as Kriegsstraßenbahnwagen, in Polish; TRAME WARS WAKE, and KSW in short. The Germanian wagon was developed at Düsseldorfer Waggonfabrik in Düsseldorf, and produced in 1943-1950. The problem was that the Sanok SN2 engine wagon and the Sanok PN2 trailer wagon was much better than the Germanic structure, and was produced in 1938-1939. However, top -down decisions marked the Germanic structure and were introduced into production as Konstal N. Because there was a lack of electric motors, the first Konstal N trams, was made as trailer cars, which were marked with Konstal ND. At the same time, narrow -gauge versions were developed, which were marked with 2N and 2nd, respectively. From 1953, modifications of N+ND tram were produced, followed by 4N+4ND, 5N+5ND, 4N1+4ND1 and 5N1+5ND1. In 1962, the Chorzów plant left the last tram from the Konstal N family.

On September 15, 1948, the Minister of Industry and Trade in consultation with the Minister of the Treasury and the President of the Central Planning Office, issued an ordinance on the creation of a state -owned enterprise; Chorzów steel structure factory, in short Konstal. The company was subject to the supervision of the unification of the rolling stock industry and railway equipment in Poznań, in short Tasko. These changes had no influence on the functioning of the company. The communists simply shared influence and power.

In 1947, the production of two -axle self -relief carbides began in the Ziehl system for narrow -gauge rails and industrial plants.

In the period 1947–1949, the plants in Chorzów built 13 trailer wagons for electric access railways modeled on the English Electric production vehicles from the 20 years of the 20th century.

In 1949, the production of self -relief wagons for transporting 15W sand, for sand rails, began. These are three -axle wagons that are equipped with rolls at both ends of the chest. One rollers are higher lower. The wagon enters the sand bridge, which has permanent rails on the sides. The wagon is in motion all the time, about 5-10 km/h. Rollers enter the rails and the box rises. At the same time, the two -part floor floats in the central axis and breaks down, and the sand spills sideways. Around 1953, the 22W sand wagon version was produced, which has a brake booth.

From 1949 to 1992, mine locomotives were built in the factory.

In 1955, the factory produced mainly freight railway wagons, trams and mine locomotives.

In 1956, a wheelchair construction department was liquidated, which produced 4,590 prams throughout its existence.

From 1953, the construction department has assembled indoor wagons, the self-component Hopper-Dozator system and wagons with recessed floors that could transport loads of 40, 100 and 120 tons. Hopper-user wagons are intended for transporting and laying the crushed stone during renovation and modernization of railway infrastructure. Laying the ballast takes place when driving at a speed of 3-5 km/h, after pneumatic leaving the dispenser to the desired level and opening the discharge flaps. You can pour the crumple on one side or the other and the center between the rails. An employee operating the wagon goes next to the wagon and controls the flaps using the control lever.

In 1958, the export production of rolling stock for socialist countries began, mainly for CCCP.

In 1957, the Konstal company undertook the production of multi -axis bow wagons for transporting heavy and large -size devices, such as turbogenerators and transformers. The first was a 18Z 18Z 18z bow wagon with a capacity of 164,000 kg. In 1962, a 606Z 16-axis bow wagon was built, with a load capacity of 230,000 kg. Type 606Z wagons were also built in a version for a wide CCCP track. In the period 1979–1985, in cooperation with the American company Norca, bow wagons of different axles were created: 12, 16, 32. The latter is on eight 4-axle prams, with a capacity of 500,000 kg. A wagon with 24-thousands was also created, on eight three-axle prams, with a load capacity of 250,000 kg. The Chorzów factory made a 16-axis and 24-axle wagon for Turkish railways. 24-axle and 32-axle wagons were built for Energy Remontowe Zakłady in Poland.

425V and 902V self -relief wagons were also produced.

The 902v samovable, 4-axle wagon was produced at Konstal and Zastal Zielona Góra. Normal track 1435 mm. Wagon length 10.87 m. Height 3.20 m. The gear capacity 40 m3. Own mass 20,700 kg. Total mass 60,000 kg. The wagons were with a brake booth or without a booth.

The most popular sand wagon was types; 401V, 401VA, 401VB, 401VC. Designation in PKP – FA or FAS. These wagons have been produced since 1964. Wagon for normal, 4-axle track. Length 9.29 m. Height 3.25 m. Own mass 20,600 kg. Maximum weight 57 800 kg. Chest capacity 38 m3. The wagon is unloaded during the warehouse passage through the chick -up bridge with a truss structure, with solid side bacon with a variable inclination. The wagon is in motion, about 5 km/h. The rollers of the wagon moving around the rails cause the box to lift the wagon floor and pouring sand onto the square under the bridge. It is the same unloading system used in 15W and 22W wagons. These wagons are used only in the sand railway network, functioning in the Upper Silesian Industrial District, due to the side rollers have a gun of the rolling stock. The 401VC wagon structure was developed in 1986 and was produced by Konstal. Compared to the 401V version, it differs in changed trucks and other construction details.

The Konstal company has been built in the 213Z container platforms, 450R fuels, 451R liquefied gas tanks.

In 1965, the factory began to build large self -loading wagons of the Talbot system. The first order for 406V wagons was placed by the GDR. The 406V self -lining wagon is intended for brown coal transport. Normal track 1435 mm. Load capacity 57,000 kg. Own mass 24,500 kg. Wagon length 13.50 m. Width 3.09 m. Height 3.33 m. Capacity 75 m3. Pneumatic KE-GP pneumatic brake with CE-1C timing valve. Screw clutch 850 kn. Hand and pneumatic unloading. Maximum speed 100 km/h. The smallest arc radius of 80 m. Construction from 1963.

In the following years, the 410V version was produced, equipped with a box heating, and in 1981 and 1982, 1000 copies of 424V wagons were delivered to Iraq, a 410V type variety.

Type 409V and 409VA self -compacting wagon, i.e. a structure developed in 1965. The wagon is intended for the transport of loose materials. Normal -gauge wagon 1435 mm. Own weight 22,000 kg. Load capacity 57,000 kg. Wagon length 10.69 m. Box width 2.63 m. Wagon height 3.33 m. The gearbox capacity 25 m3. 1xta trolley type. Oerlikon complex brake with the timing valve EST3E. Maximum speed 80 km/h. 8 feather springs. Minimum arc radius 90 m.

In 1975, the production of Self -component 902V wagons for 1520 mm for CCCP and 411V Normal -gauge types was moved from the Zastal factory.

411V Samo -Topic Samova Wagon PKP FADS or PKP FACC. HOPPER SYSTEM SYSTEM DISCOUNT. The wagon is intended for laying the track bed and transporting crushed stone. Track width 1435 mm. Own mass 21,900 kg. Load capacity 49,500 kg. Wagon length 11.19 m. Width 3.05 m. Height 3.19 m. Capacity of the box 38 m3. TYPE TYPE OF 2XTC/2XTA. Wheel diameter 0.96 m. Oerlikone combined brake with es3e timing valve. Pneumatic unloading installation. Maximum speed 100 km/h. The smallest arc radius of 75 m. The structure was developed in 1966. Production was carried out at ZBK “Zastal” and the Konstal factory. The standard -gauge version was manufactured in the 411VA version for Hungary, 411vb for Albania, Morocco and Poland, 411vb/1 for Bulgaria and 411VC for Czechoslovakia. In addition, in the period 1977-1979, a small series of self-relief wagons was created for transporting a 416V crushed stone, whose structure was based on the 411V type.

In 1983, a developmental version of 416V wagons was created marked as 425V. Versions 425VA and 425VB went to Iraq, and 425VC to Hungary. 416V self -lining wagon. Purpose for the transport of crushed stone and dosing of unloading in the construction of railway tracks. Maximum speed 100 km/h. Own weight 24,000 kg. Total mass 56,000 kg. Unloading with a pneumatic installation. Control from the platform from the control board. Capacity 36 m3. TYPE TYPE 25TNA. Minimum turning radius 75 m. The brake installation of Oerlikon, Knorr or Dako, depending on the desire of the contracting authority. Development of the structure in 1978.

The 426V type wagon is a 4-axis self-component wagon of the Hopper Dobrytor system, designed for transporting and laying the crushed stone on the tracks. The unloading system is controlled from the wagon platform using controllers. The wagon was developed in the Konstal office in 1982. Maximum speed 100 km/h. Own mass 24,500 kg. Maximum weight 55,000 kg. Chest capacity 30 m3. TYPE TYPE 25TNA. Minimum track radius 75 m. Knorr brake installation.

The 418VC type wagon, the FAS series, is a self -component Dumpcar wagon. The wagon is 4-axis, designed for the transport of loose materials, for example: sand, gravel, crushed stone, slag. It has a tilted chest on both sides with the help of pneumatic cylinders, with sides opened with a lever mechanism during tilt. 45 degrees angle. The wagon was developed by OGRPS in Poznań in 1975, with the intention of export. The production lasted in the period 1977-1992, through the Zasal factory in Zielona Góra and finally production in Konstal. Length 12.54 m. Height 3.20 m. Own mass 29,000 kg. Total mass 52,000 kg. Gearbox capacity 31 m3. Minimum arc radius 75 m. Maximum speed 100 km/h.

From 1980, wagons were produced for the transport of types of 623Z and 623z type containers, followed by 624Z and 624z varieties. In 1989, these wagons were exported to Spain as type 625z. The wagons were well made and attractive in price, which is why another order was received. In 1990, the InterContainer company bought 429Z and type 429ZR wagons, in 1992, type 430Z, and 1993, type 432Z wagons.

Production of freight wagons:

1960 – 518 copies. 1961 – 623 copies. 1962 – 691 copies. 1963 – 803 copies. 1964 – 828 copies. 1965 – 624 copies. 1966 – 844 copies. 1967 – 497 copies. 1968 – 324 copies. 1969 – 655 copies. 1970 – 653 copies. 1971 – 770 copies. 1972 – 750 copies. 1973 – 750 copies. 1974 – 923 copies. 1975 – 1,036 copies. 1976 – 1,140 copies. 1977 – 1,21 copies. 1978 – 1,056 copies. 1979 – 954 copies. 1980 – 945 copies. 1981 – 514 copies. 1982 – 743 copies. 1983 – 645 copies. 1984 – 315 copies. 1985 – 380 copies. 1986 – 481 copies. 1987 – 475 copies. 1988 – 531 copies. 1989 – 484 copies.

Trams.

In 1959, the first 13n tram was built modeled on the Czechoslovak T1. This was not satisfied with the Czechs.It was the last type of tram, whose project was made by the central construction office of the Rolling Stock Industry in Poznań.

In 1967, a 102n articulated tram prototype was created, and in 1970 the first 102NA car left the factory, referring to the 13N wagon and the 802N narrow -gauge information series. In 1973, a 105N prototype car was created, in 1977, its narrow -gauge type 105NW. In 1978, a small series of 805N wagons was made with a type of 105NW. In 1979, the first changed version of 105N appeared marked as 105NA. The 105N type tram is the most popular Polish tram. A new low-floor tram was developed in 90-year But more energy was placed in the modernization of 105N wagons.

Alstom (since 1997).

In 1989, socio-economic changes occurred in Poland. The communists transformed into businessmen and entered the national property. There was no lustration and decommunization. Thousands of industrial plants, without the support of central authorities, lost their outlets. Thousands of employees were unemployed. There was a great social crisis. The Konstal plant in November 1993 had to join the Universal Privatization Program. On September 19, 1994, by a notarial deed, the plant was transformed into a sole proprietorship of the Treasury, called Konstal. Employees received 15 % of shares, 25 % received the State Treasury, 60 % received the National Investment Fund (NFI). The governments in Poland at that time sought to sell the company to anyone as soon as possible, and most often to Germanic people.

Shortly after the company was brought to Konstal to NFI, the Linke-Hofmann-Busch plant from Salzgitter, which was part of the Geco Alsthom group, was looking for a partner in Central Europe. After considering the offers of various enterprises, the Chorzów plants were chosen, which were ordered to produce 580 chassis for freight wagons. Thanks to this cooperation, the factory resumed the construction of tanker wagons before the war. Type production began; 450r, 451 and 210r

In December 1996, the Extraordinary General Meeting of Shareholders adopted an increase in Konstal’s share capital and the possibility of buying the company’s shares by GEC Alsthom. This purchase had to be accepted by the Minister of the Interior and Administration and on February 21, 1997, he issued a positive decision in this matter. On February 28, 1997, a contract was signed, under which GEC Alsthom bought a package of shares belonging to NFI. In June 1997, the concern also bought all shares belonging to employees and most of the actions collected by the State Treasury. A new supervisory board was established, which appointed a new board. On June 22, 1998, GEC Alsthom changed its name to Alstom. At that time, the Chorzów plant received the name Alstom Konstal.

At the same time, with organizational changes, restructuring and modernization of the plant infrastructure began. In March 1997, the Department of Tanks of the Cisterc was launched, at the turn of 1997/1998, the shotfit was opened, and in 1998, the paint line was put into use. A new hall was erected from scratch and the roofs of other halls and roads were renovated at the plant. A program of courses and trainings has been started to improve the crew’s qualifications. At the end of the 90-year, the plant employed only 900 employees. The company construction office was liquidated.

Alstom Konstal at the beginning of his activity, as part of an international holding, began producing new types of freight wagons, but trams remained the basic activity of the factory. In the period 1998–2001, the company provided Polish cities with low-floor trams 116N, NGD99 and 116ND and normal-105N2K/2000.

The 105N tram family has become the longest and most produced tram in Poland. In the period 1973–2001, a total of 3,500 trams in over 20 varieties, standard gauge and narrow gauge were created.

At the beginning of the 21st century, Alstom decided that Chorzów Alstom Konstal is to deal with building metro wagons. In the period 2001–2005, the company produced and delivered 14 Metropolis 98B trains for the Warsaw metro. Until 2005, the plant completed orders for Citadis trams for Staambuł and metro trains Metropolis for Budapest and Amsterdam, and also took part in the production of Coradia and Coradia Lint vehicles for foreign carriers.

Whole rail and tram wagons are produced in Chorzów. In a special route frame, individual construction profiles that are welded are installed. Except for external sheets are applied. Railway wagons are made of stainless steel, and the subway wagons are made of aluminum alloys. The frames are rotated, thanks to which there is good access to all welds. In this way, a roof, sides and floor are made. Then the individual elements are combined into one box. This process is performed in so -called “cathedrals”. The front and rear walls are added. The box is transferred to the paint shop in another part of the hall. Transport takes place with the help of “traverses”, which are multi -meter and transport entire wagons between the halls. After varnishing, the wagon goes to the installation of the equipment. Insulation and fire compartments are installed first. Capillary and other installations are installed. Wall cladding, ceiling, floor, lighting, information system, monitoring, toilets in a closed system, armchairs, handles and handrails are installed. It is worth mentioning that a compact toilet is a mass of about 400 kg. Windows and automatic doors are installed. In the case of a composition adapted to move at a speed of 200 km/h, the technology of pasteing the window from the inside is used, which guarantees increased safety. The door assembly method also depends on what train is being built and at what speed it will move during operation. The last stage is the receipt of the wagon by the contracting authority and shipping. Motor wagons are made with or without a cabin for a limited network, for example internal communication at airports or subway. In Chorzów, the production takes place in two shifts.

In 2007, Alstom Konstal resumed the production of entire trains. This year, the factory employed about 400 employees. Employment increased very slowly. In 2011, there were 516 employees, and in 2012, 800 employees, in 2016, 1,100 employees. In 1997-2012, Alstom invested about PLN 267 million in Chorzów.

In 2012, two production halls were opened at the Alstom factory in Chorzów. The value of the investment was PLN 33 million. On December 6, 2012, a new paint shop and a production and assembly hall were opened at the plant. The new facilities allowed to increase the efficiency of 20 wagons per month. In 2019, the production volume of up to 50 wagons per month could be achieved.

On November 4, 2016, Alstom Konstal signed a partnership agreement with the Silesian University of Technology, pursuant to which graduates of the Faculty of Technology (myth) have the option of implementing half -year internships, with the option of employment.

From 2017, the factory began the production of metro trains for Dubai. These were the wagons of the Alstom Metropolis family, in the amount of 50 copies, without the driver’s cab, i.e. automatically controlled from the center. A second production line was launched for the production of this order. Employment was increased to 1,200 people.

Also in 2017, a contract was concluded for metro wagons for Riyadh in the capital of Saudi Arabia. The contract included 69 metro compositions, worth EUR 300 million. Passengers of 69 two -wagon warehouses can use compartments for the first, second and family classes.

At the end of November 2018, a new assembly line was opened, intended for the production of Intercity Next Generation trains, called Coradia Stream ordered by the Dutch national carrier Nederlandse Spoorwegen. Tram wagons are primarily the constructions of Alstom Citadis.

In 2021, the French company Alstom took over the Canadian Bombardier Transportation plant and became one of the global leaders in the production of rail rolling stock. After the merger, Alstom became the second, after Chinese CRRC, a manufacturer of rail rolling stock in the world. The concern currently employs 75,000 employees in 70 countries. However, this does not affect the plant in Chorzów, whose profits flow from Poland.

In 2023, Alstom in Poland has been present for twenty years and employs a total of 2,700 employees (also the Bombardier plant in Wrocław), it is also an important workplace in Upper Silesia. The company Alstom Polska, operates in four locations: Warsaw, Chorzów, Katowice and Wrocław. The plant in Chorzów has been operating as the Alstom Konstal group since 1997. The plant specializes in the production of metro trains and regional trains. The plant in Chorzów has completed orders, among others, for recipients in Italy, the Netherlands, Norway, Belgium, Hungary, for the Baltic countries and the Arab Emirates. In addition to the metro trains in Warsaw, there are no other trains produced in Chorzów used in Poland. 40 % of elements and components for the production of wagons in Chorzów are obtained in Poland. The plant in Chorzów has 160 hectares in the vicinity, which can be adapted to new halls. Address Alstom Konstal S.A. ul. Metalowców 9. 41-500 Chorzów.

Written by Karol Placha Hetman